Recycled Rubber Flooring

- Slip Resistant, even when wet

- Use interior or exterior

- Easy to Install and Maintain

- Scuff and Stain Resistant

- 5 Year Wear Warranty

- Impact & Shock Absorbent

Recommended Applications:

- Exercise & Weight Rooms

- Ice Rinks / Locker Rooms

- Basements / Playrooms

- Workshops / Hobby Rooms

- Pet & Utility Areas

- Mud Rooms / Storage Areas

- Commercial / Industrial Spaces

Product Dimensions / format

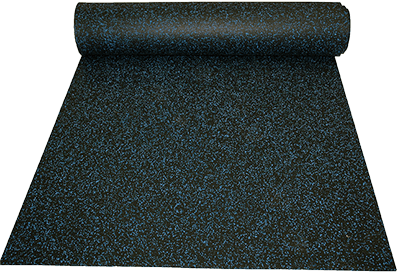

Rolls

Width: 48″

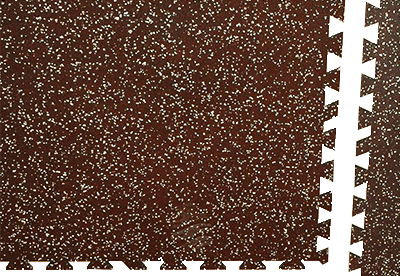

Interlocking Tiles

Size Module: 36″ x 36″

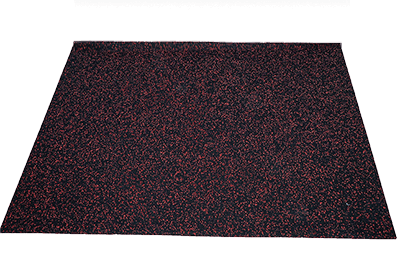

Square Tiles

Size Module: 36″ x 36″

Standard Thicknesses

| US Measure | Metric |

|---|---|

| 1/4″ | 6.35 mm |

| 3/8″ | 9.5 mm |

| 1/2″ | 12.7 mm |

Environmental Attributes

Our product is high quality recycled rubber material made using scrap rubber from the recycling of truck tires and virgin rubber materials, saving energy, reducing oil consumption and keeping millions of pounds of tire waste out of landfills.

Powerhold Rubber Flooring conforms with indoor air quality and Volatile Organic Compound (VOC) emission requirements and is itself a recyclable product.

LEED & Powerhold Rubber Flooring

MR 4 – Recycled Content – Up to 90% Post Consumer Recycled Content

EQ 4 – Low Emitting Materials/Adhesives Specified Adhesives Meet SCAQMD 1168

Powerhold Recycled Rubber Custom Roll Length Program

No Standard Roll Lengths = Reduced Waste and Seams

Order a Minumum of 120 s/f (30 l/f) and Additional Lengths in Full 1 Linear Foot Increments

Quick Ship Rolls Goods Program

Ships in 6 Working Days!

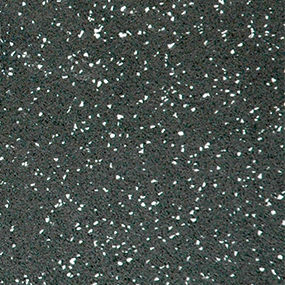

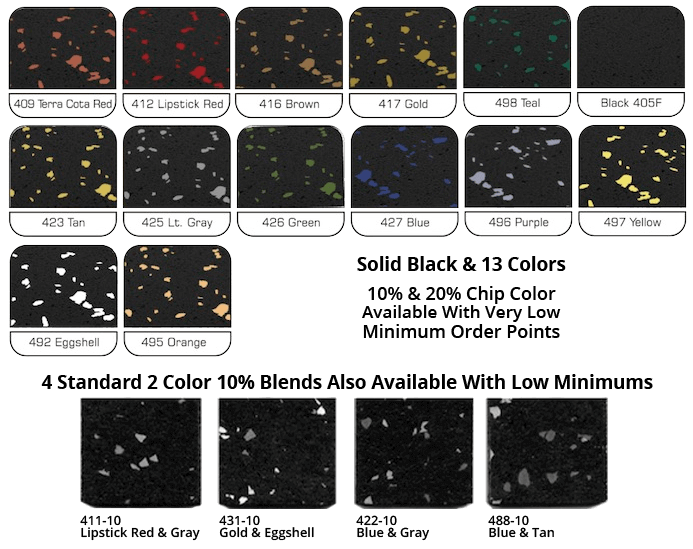

1/4″ Quick Ship Colors:

- 10% Terra Cotta Red

- Green

- Blue

- Tan

- Eggshell

- Gray

- Solid Black

3/8″ Quick Ship Colors:

- 10% Terra Cotta Red

- Green

- Blue

- Tan

- Eggshell

- Gray

- Solid Black

Quick Ship 36″ Interlocking Tile Program

Ships in 2 Days*

1/4″ Quick Ship Colors:

- 20% Tan

- 20% Blue

3/8″ Quick Ship Colors:

- 10% Gray

- Blue

- Tan

- Solid Black

*Limited quantities available as Quick Ship Items

3/8″ Tiles Available as Center, Corner & Border Tiles

| Test Method | Powerhold Typical Value | |

|---|---|---|

| Durometer, Shore A, Points of Hardness | ASTM D2240-97 | 60 |

| Density, lbs/ft |

ASTM D297-93 Part A, Section 16.3 | 64 |

| Compressibility @ 100 psi, % | ASTM F36-95 | 12 |

| Recovery, % after 100 psi compression | ASTM F36-95 | 85 |

| Flexibility | ASTM F137-71(1994) | F=1 |

| Tensile, psi | ASTM D412-98a, die C @ 20ipm | |

| With Grain | 600 | |

| Against Grain | 450 | |

| Tear, ppi | ASTM D412-98a, die C @ 20ipm | |

| With Grain | 150 | |

| Against Grain | 120 | |

| Compression Set, %, 22 hours at 158°F | ASTM D395-98, Method B | |

| 25% deflection | 40% | |

| 50% deflection | 30% | |

| Coefficient of Friction | ASTM D1894-95 | |

| Dry | 1.33 | |

| Wet | 1.55 | |

| Critical Radiant Flux | ASTM E 648-99 | 0.1 W/cm2 |

| Flammability and Flame Spread | DOC FFI-70 CSPC | Pass |

| Indoor Abrasion, % of Material Loss | ASTM C501-84(1996) | 0.24 |

| Resistance to Chemical Attack | ASTM F925-97 | |

| Ammonia | No surface attack or color change | |

| Bleach | No surface attack or color change | |

| Disinfectant | No surface attack or color change | |

| Alcohol | No surface attack or color change | |

| Tide | No surface attack or color change | |

| 5% NaOH Solution | No surface attack or color change | |

| Human Sweat | No surface attack or color change | |

| Instrumented Impact, absorbed energy at rupture, ft/lbs | ASTM D3763-00 | 20 |

| Static Load Limit, residual compression | ASTM F970-98 | .0016* |

| Rubber in Compression, % deflection | ASTM D575-91, 500 lb. Load | 43 |

| Compression Endurance | 10,000 fatigue cycles at 50% displacement | 5% set |